version 3/27/2021

Many organisms pathogenic to plants reside in the soil and can contaminate even "soilless" mixes used to propagate plants in nurseries. Using pathogen-free potting media is an essential starting point for producing nursery container stock that is free of soil-borne plant diseases. Diseased plant material that is outplanted can introduce pathogens from the container into the new planting site. If conditions are suitable, these pathogens can affect not only the transplanted stock but may spread beyond the planting sites into the environment where thay can affect other vegetation.

Heat treatment is often referred to as sterilization, but temperatures routinely used to heat soil will not result in completely sterile soil or potting media. The goal is to heat the potting mix to a point that kills the plant pathogens of concern.

Related pages - Phytosanitary Procedures for BMPs for Producing Clean Nursery Stock sections 1.2. Heat treatments and 2.4. Heat treatment of potting media

Heat treatment of soil or potting mix involves reaching a target temperature for a minimum treatment time. In general, lower temperatures require a longer heating time to achieve the same degree of kill of plant pathogens. Moist heat is also more effective than dry heat at any given temperature.

All portions of treated soil or potting mix needs to reach the target temperature for the minimum treatment time. Begin timing when the coolest area of the treated mix reaches the target temperature. Uniformity of heating can be affected by a variety of factors, including variation in compaction, moisture, clods, bin shape, and method of heating. The coolest part of the heated mix may be at the center or near the edge, depending on these factors.

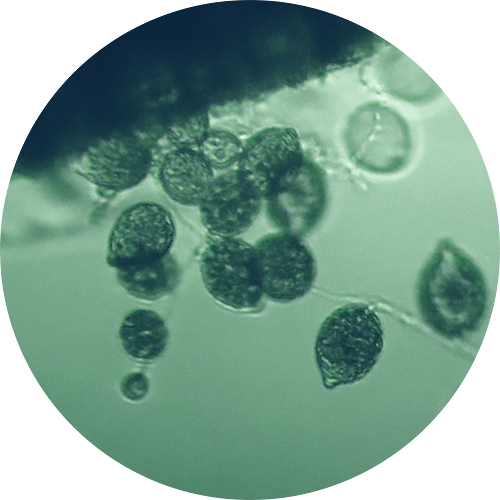

Heating moist soil to 140°F (60°C) or higher for at least 30 minutes will kill propagules of Phytophthora and other water molds as well as most plant pathogenic fungi. If you are unsure whether you are measuring the temperature in the coolest part of the treated mix, you can increase the margin for error by extending the duration of heating (e.g., 140°F (60°C) for at least 1 hour) or by increasing the target temperature (e.g., 158°F (70°C) for 30 minutes). As noted under Q5, you can avoid the potential phytotoxicity problems that can develop in some soils by using a maximum temperature of 180°F (82°C) or less.

| Moist soil, 30 minutes at | Organisms killed |

|---|---|

| 120F (49C) | watermolds (oomycetes) |

| 145F (63C) | most plant pathogenic fungi, bacteria, and viruses, worms, slugs, centipedes |

| 160F (71C) | plant pathogenic bacteria, soil insects |

| 180F (82C) | weed seeds |

| 212F (100C) | heat resistant plant viruses and weed seeds |

Source: Baker, K.F., 1957.

Other recommended time / temperature treatments

Place temperature probes in the coolest portions of the treated soil or media. You may have to use several probes to determine which areas are the coolest. Begin timing the heat treatment once the probes show you have reached the desired temperature at the coolest spot. Continue to monitor temperature to ensure that it does not drop below the target.

For all temperature measurement and recording devices, check manufacturer specifications to ensure that the probe is rated for a temperature range that extends above your target temperature so the probe will not be damaged if the temperature exceeds your target. Some temperature measuring devices may also need to be protected from moisture.

Thermometers. Long-stem thermometers such as compost thermometers can be used if they can be mounted so that the gauge remains outside of any coverings used during soil heating. These thermometers use a straight rigid metal probe of various lengths that are inserted into the soil. Both analog and digital versions are available; digital thermometers typically respond faster and are more precise. Digital thermometers with wired or wireless external temperature probes can also be used. These provide more flexibility for placement of the probe in the soil than thermometers with long straight probes.

Temperature Loggers. Temperature loggers can both measure temperature and store the temperature data in internal memory for downloading or transmit temperature data wirelessly to another device. Temperature loggers with external wired probes are available in a wide variety of prices from multiple manufacturers. If using a wired external probe, the wire needs to be long enough to extend from the desired temperature monitoring location(s) to a point where the logger can be safely placed.

Button-style temperature loggers are buried directly in the media and need to be recovered for downloading and reuse. Most require specific readers to download the data.

Temperature indicating strips. Another option for monitoring temperature is non-reversible temperature indicating labels, stickers, or strips. These single use temperature indicators are attached to items and indicate whether they have reached a specific temperature. Different versions of these products can indicate whether a specific temperature was exceeded or show a range of temperatures that allows the user to determine the maximum temperature attained. The indicators in these strips typically react within one to a few minutes, so they do not provide information on the length of time that the maximum temperature was maintained.

The most common means of heating soil are by free-flowing steam (i.e., not under pressure) or by various dry heat sources, in which heat is generated by electricity, propane or natural gas, or solar energy. If the heat source is dry, the soil will need to be moistened before treatment. An important point to consider is the scale that will be needed to handle the amount of potting mix used in production. Some heating processes are better suited for treating large batches at once, others are more efficient for small batches. A custom-built apparatus that is specifically tailored to your specific needs and constraints may be the most economical over the long term.

In general, the efficiency of heating media can be increased by mixing the soil during the heating process. Mixing soil or media during heating greatly improves the uniformity of heating and reduces the time needed to reach target temperatures. Static heating of soil and potting media is typically subject to hot and cold spots.

Steam. Steam is an efficient means for supplying moist heat. Steam can be produced using a steam boiler or a steam generator. A search on "soil steam sterilization equipment" will primarily return information on large commercial grade equipment typically used in agriculture and nurseries. However, depending on the amount of soil you intend to treat at a time, smaller, less expensive equipment (steam generators, commonly heated using electricity) capable of producing dry steam may be feasible. The use of dry steam (i.e., vaporized water, without liquid water droplets) is important for two reasons. First, steam transfers heat as it condenses, so steam in the vapor phase will heat soil more efficiently than droplets of hot water. Secondly, water has a high specific heat, much higher than soil or potting media. Most of the energy used to heat moist soil is actually needed to increase the temperature of the water in the soil. As the soil becomes progressively wetter by the condensation of water during steaming, more energy is required to attain a given temperature.

Aerated steam is made by blending steam and forced air from a blower in a plenum that supplies the steam-air mixture to the soil. A water trap is included to capture water that condenses when the steam mixes with the cooler air. Compared with steam, which is 212 F (100 C) at atmospheric pressure, steam-air mixtures can be adjusted to a range of lower temperatures. This allows you to consistently heat to a target temperature below 212 F (100 C) and avoid excessive heating of the soil or other materials (e.g., containers made of some plastics).

Steam and aerated steam heat potting mix efficiently because they diffuse through porous media. Denser, less porous materials, such as heavy soils, are much more difficult to heat uniformly via steam unless the material is agitated and separated into small fragments during heating. Static steaming of porous potting mix in containers and piles can show poor uniformity, resulting in long steaming times to adequately heat the coolest portions of the soil mass. This can result from steam preferentially moving through areas with low resistance, such as along the walls of the container or through fissures that develop in the media (known as blowout). This issue was studied in detail by Baker and Fuller (1976) and is affected by how and where the steam is introduced. The problem is minimal if soil depth is less than 1 ft (30 cm).

Dry heat. Electric soil sterilizers are one option for heating soil or potting media, typically for relatively small volumes. Some other possibilities include commercial moisture-proof heating equipment used in other industries (e.g., search "food warming equipment" and "towel warmer cabinet") for low cost alternatives for small operations. Asphalt kettles or kettle melters or similar equipment with adequate temperature controls may provide another option for heating larger volumes of soil.

Rotary kilns are commonly used to heat granular materials. They can be quite efficient and most commercial equipment is designed for very large amounts of material. However, it is possible to scale down these devices to sizes that may be more appropriate for nursery uses. We have constructed and tested a version of a rotary kiln for heating soil that uses an insulated cement mixer to tumble the soil and portable propane forced air heater as a heat source. Because heating occurs more quickly in this type of device, the amount of fuel needed to attain target temperatures is minimized.

In areas with sufficient solar exposure, a solar oven can be used to reach the target temperature. Even if conditions are inadequate to reach target temperatures with solar heating, preheating soil using solar energy can reduce the amount of time and energy required to heat media using other methods.

Greisbach et al 2012 recommend pasteurizing soil by the use of aerated steam. They illustrate several different types of steaming units (p.52).

Baker 1957 discusses the principles of heating soil in great detail in chapter 9 and compares a variety of heating units in chapter 10. Although this reference is old, the physics of soil heating have not changed. Practical tips and relevant data are provided.

Stapleton et al 2008 describe and illustrate a method for using solarization to heat treat soil in containers.

Heat-treated soil can readily become recontaminated with soil-borne plant pathogens in numerous ways, including:

- placing treated soil into contaminated equipment, vehicles, bins, or pots

- handling treated soil with contaminated implements or hands

- planting pathogen-contaminated propagules or seed

- introducing contaminated water via irrigation or splash from contaminated soil

- placing treated soil on the ground directly or in pots that have been on the ground or on contaminated surfaces

The key to avoiding soil-borne pathogens is to start clean and stay clean. If you allow your clean, heat treated potting media to become contaminated afterwards by poor handling practices, you are wasting the time and money spent for the heat treatment. Details about practices used to prevent recontamination of clean, heat-treated media are discussed in the Best Management Practices (BMPs) for Producing Clean Nursery Stock

Heating soil or nursery mix to excessively high temperatures will use more energy than is required and can eliminate beneficial microorganisms that may be present. Excessive soil heating (greater than about 180° F [82°C]) may also increase the chance of phytotoxicity due to exchangeable manganese, ammonium, soluble salts, and toxic organic compounds that are formed at high temperatures (Dawson et al. 1965). It is safe to treat a UC-type soil mix (fine sand and sphagnum peat moss or hypnum peat moss) to a temperature of 212F (100C) without developing soil toxicity to plants. Soil mixtures high in readily decomposable organic matter such as manure, leaf mold, or compost (Baker 1957, p129) or high amounts of manganese are most likely to become phytotoxic when exposed to excessively high temperatures.

Phytotoxicity due to exchangeable manganese will decrease over time as this element reoxidizes. If treatment temperatures are higher than 180° F (82°C), soil should be aged before use to minimize the likelihood of manganese phytotoxicity. Reoxidation of manganese to insoluble forms is greatly accelerated by the activity of soil bacteria, whose populations are also reduced or eliminated at high temperatures (Sonneveld and Voogt 1975).

As noted above, typical heat treatment temperatures (e.g., 140F [60 C] for 30 min) do not kill all microooganisms in the soil, though they are lethal to water molds including Phytophthora species and most plant pathogenic fungi. Most spore-forming soil bacteria and spores of various mycorrhizal fungi (Ellis et al. 2002, Hu et al. 2019, Sylvia and Schenck 1984) will not be killed by this treatment.

Spores of fungi known to form mycorrhizal associations with plant roots are ubiquitous in soil and are readily blown about. Studies have shown that container plants form mycorrhizal associations either in the nursery or after transplanting (for example Meyer et al. 2005). Experiments with soil heat-treated by solarization found that plants growing in recently solarized soil were well colonized by arbuscular mycorrhizae (Stapleton and DeVay 1986). In general, saprophytic fungi can colonize heat-treated soil more readily that pathogenic water molds or fungi, many of which have limited saprophytic ability. Because colonization by airborne spores of various mycorrhizal fungi occurs readily in most areas, heat treatment of potting mix does not adversely affect plant establishment and growth or mycorrhizal colonization. In general, the elimination of pathogens by heat treatment improves the health and survival of container plants, as long as pathogens are not re-introduced after heat treatment (see Q 4 above).

Some fungi that form mycorrhizae may be killed by heat treatment if very high temperatures (>80 C) are used (Ellis et al. 2002, Hu et al. 2019, Sylvia and Schenck 1984), but there is no guarantee that spores of suitable mycorrhizal fungi are present in potting mix to begin with. A typical soilless potting medium does not have a soil microbial community that has much in common with a planting site in native habitat or elsewhere. Hence, although some native plant nursery growers have expressed concern about losing beneficial microbes by heat-treating their soil mix, the benefit of eliminating Phytophthora and other pathogens greatly outweighs the potential loss of some unknown beneficial microorganisms.

Vermiculite and perlite are manufactured using very high temperatures and will be free of soil-borne pathogens as long as they haven't been contaminated after manufacture.

Commercial compost produced according the California standards may be free of most plant pathogens, but depending how the material is handled at the composting facility and afterward, has a high risk of being recontaminated. California composting facilities, depending on their size, are subject to regulations concerning minimum temperatures and duration to eliminate human pathogens.

Sand, especially quarried from rivers, is commonly contaminated with soil-borne pathogens. Sand from clean sources can also become contaminated.

Bottom line: Clean soil mix components do not look any different from contaminated components. Components that are produced and moved in bulk can easily become mixed with contaminated material in storage and transport.

Baker, K.F. Editor. 1957. The U.C. System for Producing Healthy Container Grown Plants, Manual 23. University of California, Division of Agricultural Sciences, Agricultural Experiment Station Extension Service. LINK

Baker, K.F.; Fuller, W.H.1976. Movement of steam along the sides of containers during steam treatment of soil. Hilgardia 44 (4): 83-97.

Dawson, J.R.; Johnson, R.A.H.; Adams, P.; Last, F. T. 1965. Influence of steam/air mixtures, when used for heating soil, on biological and chemical properties that affect seedling growth. Ann. Appl. Biol. 56:243-251. https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1744-7348.1965.tb01232.x

Ellis, L,E.; Waldrop, T.A.; Tainter, F.H. 2002. Ectomycorrhizae of Table Mountain Pine and the influence of prescribed burning on their survival. Pages 128-131. Proceedings of the eleventh biennial Southern silvicultural research conference. Gen. Tech. Rep. SRS–48. Asheville, NC: U.S. Department of Agriculture, Forest Service, Southern Research Station. 622 p. https://www.srs.fs.usda.gov/pubs/gtr/gtr_srs048/article/gtr_srs048-ellis01.pdf

Griesbach, J.A.; Parke, J.L.; Chastagner, G.A.; Grünwald, N.J.; Aguirre, J. 2012. Safe procurement and production manual: a systems approach for the production of healthy nursery stock. Wilsonville, OR: Oregon Association of Nurseries. 98 p. LINK

Hu, W.;Wei, S.; Chen, H.; Tang, M. 2019. Effect of sterilization on arbuscular mycorrhizal fungal activity and soil nutrient status. J. Soil Sci. and Pl. Nutrition https://doi.org/10.1007/s42729-019-00156-2

Meyer, AH.; Botha, A., Valentine, A.J. Archer, E., Louw, P.J.E. 2005. The Occurrence and Infectivity of Arbuscular Mycorrhizal Fungi in Inoculated and Uninoculated Rhizosphere Soils of Two-year-old Commercial Grapevines. Meyer, AH.; Botha, A., Valentine, A.J. Archer, E., Louw, P.J.E. S. Afr. J. Enol.Vitic., 26(2):90-94. LINK

Sonneveld, C.; Voogt, S.J. 1975. Studies on the manganese uptake of lettuce on steam-sterilised glasshouse soils. Plant and Soil 42:49-64. https://edepot.wur.nl/309624

University of California Solarization webpage LINK

Stapleton, J.J., DeVay, J.E. 1986. Soil solarization: a non chemical approach for management of plant pathogens and pests. LINK

Stapleton, J.J., C. A. Wilen, and R. H. Molinar. 2008. Soil solarization for gardens and landscapes. Pest Notes Publication No. 74145, University of California Agriculture and Natural Resources. LINK

Sylvia, D. M.; Schenck, N.C. 1984. Aerated-steam treatment to eliminate VA mycorrhizal fungi from soil. Soil Biol. Biochem. 16(6):675-676. (Looked at 30 min treatments at 50C, 60C, 70C, and 80 C. Infective propagules of Glomus clarum, Glomus etunicatum, and Gigaspora margarita were not eliminated until 80 C for 30 minutes. Non-filamentous and filamentous bacteria (Actinomycetes) were reduced but not eliminated even at 80 C). https://www.sciencedirect.com/science/article/abs/pii/0038071784900919

Updated 3/31/2021 with more information and references.