Version 3/29/2021

Phytophthora species and other plant pathogens can be killed by exposure to high temperatures for a sufficient length of time. The most common methods for applying heat in nursery operations are via:

· steam or aerated steam (steam/air mixtures)

· hot water

· dry heat (e.g., insulated or noninsulated containers heated by electricity or natural gas)

· solarization (solar heating via greenhouse effect under clear plastic or glass)

Materials to be heat-treated should be moist before treatment because target organisms are killed more readily and at lower temperatures if they are hydrated. For 30 minute heat treatments, temperatures had to be increased by up to 36 F (20 C) to kill dry propagules of some plant pathogenic fungi compared to temperatures required for propagules premoistened for 16 hours (van Loenen et al 2003). If materials to be treated (e.g., potting mix, residues on used pots) have not been kept moist for at least 12 hours before treatment, treatment temperature and/or time should be increased well above minimum standards to ensure efficacy. When wetting up dry materials before treatment, the wetting period begins when the driest part has been moistened. For example, dry aggregates of potting media would need to be wetted to their centers before you start timing the wetting period.

Effective treatment times decrease as temperatures increase. For instance, metal tools can be sterilized by exposure to flame for a short period. Standard treatments for killing plant pathogens in water include 203 F (95 C) for 30 seconds and 185 F (85 C) for 3 minutes (Runia and Amsing 2001). However, longer treatment times at lower temperatures are more useful for treating large volumes and bulky materials (e.g., used pots and potting media) because of the time required to uniformly heat the materials to the desired temperatures without overheating. Based on multiple studies, heating of moist materials to 140 F (60 C) or higher for at least 30 minutes will kill propagules of Phytophthora and other water molds, as well as most plant pathogenic fungi.

In all heat treatment procedures, the timing of the heat exposure period starts when the coolest portion of the heated material reaches the target temperature. Total heating time can be reduced by ensuring that that treated materials are as warm as possible before treatment; preheating via solarization or simply warming materials in the sun will help reduce energy needs. Total heating time will also be minimized if the heated material (e.g., water, potting media) is agitated and heat of the material is uniform, without cold spots. In all heat treatments, some margin for error should be allowed to account for non-uniform heating. Increase treatment times substantially beyond the minimum requirement if it is difficult to ensure uniform heating.

Potting mix, containers, and other materials can also be solarized. In some locations a solar oven can be used to attain the typical heat-treatment standard (140 F (60 C) for at least 30 minutes). Solar ovens are most effective where direct sunlight is available for 5 hours around solar noon during the longer days of mid spring through mid fall and when ambient temperatures are 70 F (21 C) or higher.

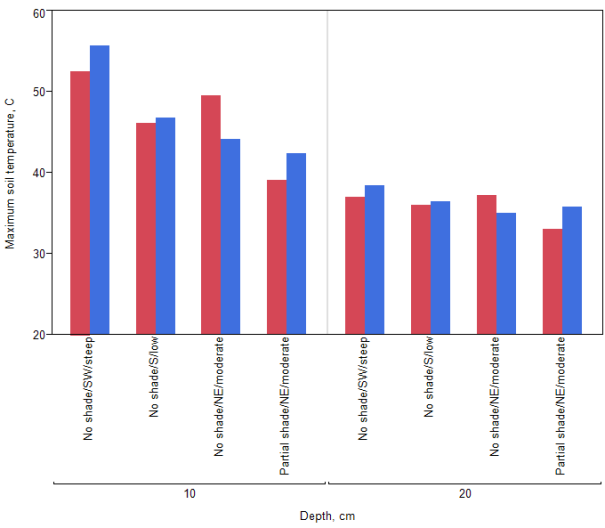

Standard soil solarization can also be used to heat soils in nursery bench beds, planting sites, etc., and can be used to disinfest contaminated surface soils. Soil solarization can be effective at heating surface soils, but temperatures effective for killing Phytophthora may be difficult to attain at soil depths greater than about 20 cm (Figure 1). Heating is affected by the duration of continuous sunlight during peak hours and can be affected by slope, aspect, and shading. Because subsurface soil temperatures attained through solarization are typically no more than 110-125 F (43-52 C), treatments need to be conducted for an extended period to reach adequate time X temperature thresholds. Typical treatment duration for solarization of surface soil is 4 to 6 weeks during summer, but longer treatment periods may be needed in situations where solar heating conditions are more variable. A calculator for estimating the minimum solarization times and depth of heating in nursery beds is available online at http://uspest.org/soil/solarize.

Figure 1. Maximum temperatures at 10 and 20 cm depths measured between February and 1 October 2015 for two solarized planting sites in each of 4 plots with different levels of shading (from Pinus sabiniana trees), aspect, and relative slope. Sites were solarized with of two layers of 6 mil clear thermal anti-condensate plastic greenhouse film (1.2 m squares). The solarized area was near the minimum area that can be used to achieve acceptable temperatures at the center of the site; lower maximum temperatures will be attained near the edge of the plastic film.

Phytophthora species and other water molds are relatively sensitive to heat (Table 2). The differential between the temperatures that are lethal to Phytophthora and to plant propagules (seeds, bulbs, cuttings, etc.) provides an opportunity for freeing plant propagules from these pathogens through carefully-controlled heat treatments. Vegetative plant materials tend to tolerate heat treatment better if they are in a dormant condition, under slight water stress, and have low nitrogen levels. Plant materials should be selected or preconditioned to be in their most tolerant state before treatment.

| Moist soil, 30 minutes at | Organisms killed |

|---|---|

| 120F (49C) | watermolds (oomycetes) |

| 145F (63C) | most plant pathogenic fungi, bacteria, and viruses, worms, slugs, centipedes |

| 160F (71C) | plant pathogenic bacteria, soil insects |

| 180F (82C) | weed seeds |

| 212F (100C) | heat resistant plant viruses and weed seeds |

Source: Baker, K.F., 1957.

9/15/2020 - added temperature sensitivity data from Baker 1957. -3/29/2021 - added information on solar ovens and soil solarization and Figure 1.

Related pages - Using heat to eradicate soil-borne plant pathogens from nursery potting media ("soil sterilization") and Phytosanitary Procedures for BMPs for Producing Clean Nursery Stock section 2.4. Heat treatment of potting media