Standard spray application equipment can be used to apply phosphite to the bark. A high rate of an organosilicate surfactant (trade name Pentrabark®1) is mixed with the phosphite solution to enhance absorption through the bark. The efficacy of the bark spray applications are still being tested in the field. In several field trials, preventative bark spray applications made as specified below have failed to lower SOD incidence and mortality rates in treated tanoak trees compared to nontreated trees.

Timing: Spray trees at least 4-6 weeks before the onset of favorable disease conditions to allow for uptake and translocation. Two applications are recommended in the first year (fall-spring or spring-fall), followed by annual applications thereafter. Based on results of field studies noted above, this regime may not be adequate to protect large tanoaks.

If the bark is saturated by rainfall at the time of application, spray will run off sooner, which may lead to reduced absorption. Otherwise, phosphite uptake is not adversely affected by rainfall. Light to moderate rainfall after application can rewet residues on the bark surface and may provide additional bark uptake. Phosphite that washes off the trunk into the soil is inactivated by soil microorganisms within a few weeks.

Dose: For the bark surface application, potassium phosphite (45.8 percent potassium phosphite) is diluted 1:1 with water. Pentrabark® surfactant is added to attain a final surfactant concentration of 2.3 percent by volume in the spray mixture. This surfactant concentration can cause excessive foaming and may be higher than is necessary to obtain uptake. The resulting diluted spray solution contains 22.4 percent potassium phosphite or 302 g potassium phosphite/L solution (2.52 lb/gal).

Various stem characteristics and the spray equipment used can affect the point where the spray begins to run off the stem. These include:

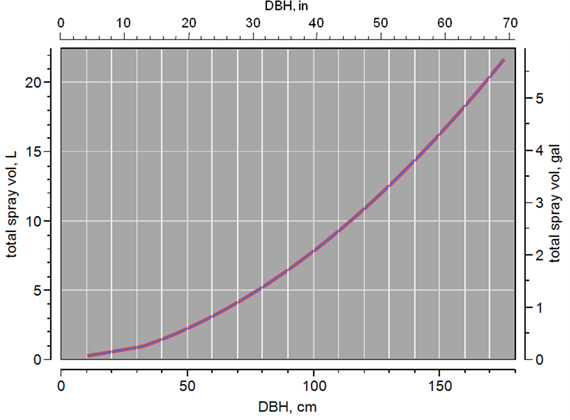

Because of these variables, it is not possible to precisely calculate the amount of spray needed to treat any tree from the label instructions alone. Figure 3-6 shows the approximate amount of diluted spray needed to treat trees of varying diameters, calculated from additional information provided by the distributor.

Figure 3-6—Approximate amount of diluted Agri-Fos® spray solution used to treat oak and tanoak stems by trunk DBH (diameter at breast height = diameter measured 137 cm [4.5 ft] above the soil grade). For trees less than 30 cm (12 inches) DBH, a linear function is used to calculate spray volume from trunk diameter. For stems 30 cm DBH or larger, the function includes a quadratic term, which causes the line to curve upward.

When phosphite is applied following label instructions, the amount of spray applied per tree will increase as the trunk diameter (and bark surface area) increases. In addition, larger trunks receive more spray solution per diameter unit because of their rougher bark. For stems less than about 30 cm (12 inches) diameter, about 31 ml of spray solution is applied per cm of trunk diameter when the lower stem is sprayed to runoff. For a 75 cm (30 inch) diameter stem, the amount increases to 62 ml per cm of trunk diameter. It is necessary to increase the amount of spray per unit stem diameter (ml/cm) as trunk diameter increases to maintain a more constant spray amount per unit trunk volume (ml/cm3).

Application procedures: The applied phosphite/surfactant solution must penetrate dead outer bark tissues and be absorbed by living cells in the bark to be effective. To facilitate uptake, direct the spray to areas where the outer bark is thinner, such as in bark fissures. Spray is less likely to be absorbed if applied to thick areas of dead outer bark or dense layers of moss on the bark surface.

Dense layers of moss on the bark surface can also decrease phosphite absorption. Target spray away from dense moss patches. Where this is not possible, use a larger spray droplet size and hold the spray nozzle close to the bark surface to spray beneath leafy mosses that extend outward from the bark. For appressed mosses, apply enough spray to wet the bark under the moss. Moss on the bark surface is killed by the phosphite/surfactant spray solution, so moss presents less of a problem after the initial phosphite application.

Brushes with stiff bristles can be used to remove moss from the portion of the stem that will be sprayed. This is very labor-intensive and may not be practical for treating large numbers of trees. Vigorous brushing can cause small wounds by chipping off bark fragments, so brushing or other mechanical moss removal should be completed several months before the rainy season.

Phosphite uptake may also be reduced if the bark surface is dusty. For dust-covered stems, apply after early rains have rinsed off the dust or use water to hose off excess dust before application. Allow the bark surface to dry after washing so that the applied spray solution will not run off immediately.

Select nozzle type and spray pressure to maximize spray deposition and minimize spray drift. Drift can be minimized by using nozzles that produce uniformly large spray droplet sizes, such as air induction nozzles. Low spray pressure (near the nozzle's minimum pressure rating) will help minimize the production of fine spray droplets that drift and will also reduce the tendency of larger spray drops to bounce off the bark surface.

Spray is commonly applied to the lower 2 m (6 ft) of the trunk to just before the point of runoff. The spray volumes shown in figure 3-6 can be used to determine the amount of spray to be applied if the treated zone is shifted upward. Applying the spray higher on the stem provides several potential advantages:

Spray can be applied high on the trunk (up to about 6 m [20 ft]) by attaching spray nozzles to a telescoping pole (fig. 3-7). Compared with basal spraying (to about 2m height) higher spraying requires some specialized equipment and more effort. High bole application also has greater potential for overspray, so the applicator should wear appropriate PPE to avoid exposure. The relative efficacy of high bole application versus basal application is currently under study.

Figure 3-7—A telescoping pole with nozzles mounted at one end can be used to apply Agri-Fos® ( phosphate) solution higher on the trunk.

Applicator safety: Most spray equipment generates fine droplets that can be inhaled, so appropriate respiratory protection is required. All sides of the stem need to be sprayed, so it may not be possible for the applicator to rely on wind to avoid spray mist. When applying at heights at or above head level, wear a waterproof hat and full face shield to prevent exposure to spray mist and solution that bounces or drips off the stem. Coveralls or waterproof outer clothing are also recommended, especially if large numbers of trees are to be treated.

1The use of trade or firm names in this publication is for reader information and does not imply endorsement by the U.S. Department of Agriculture of any product or service.